Introduction:

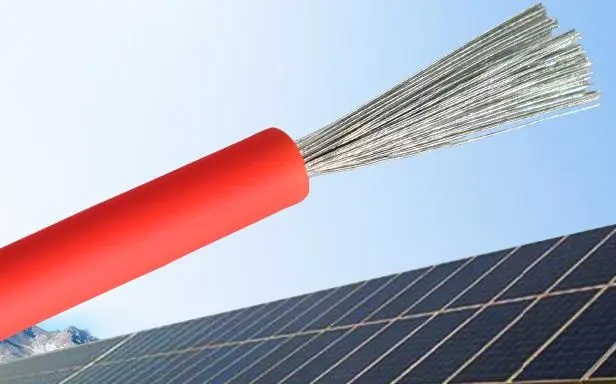

Photovoltaic (PV) systems have gained immense popularity in recent years as a sustainable and renewable source of energy. These systems require various components to function effectively, including cables that connect solar panels to inverters and other components. The insulation material used in these cables plays a crucial role in ensuring the safety, durability, and efficiency of the entire PV system.

In this comprehensive guide, we will delve into the world of PV cable insulation materials, exploring the different types available, their properties, advantages, disadvantages, and applications. By understanding the intricacies of these materials, stakeholders in the solar energy industry can make informed decisions when selecting appropriate insulation materials for PV cables.

Types of PV Cable Insulation Materials:

1. Polyvinyl Chloride (PVC):

Polyvinyl chloride, commonly known as PVC, is one of the most widely used insulation materials for PV cables. PVC offers excellent electrical insulation properties, flexibility, and resistance to moisture and sunlight exposure. It is also relatively cost-effective compared to other materials, making it a popular choice for various PV applications. However, PVC has limitations in terms of temperature resistance and environmental impact, as it is not as environmentally friendly as other materials.

2. Cross-Linked Polyethylene (XLPE):

Cross-linked polyethylene, or XLPE, is another commonly used insulation material for PV cables. XLPE offers superior thermal and electrical properties compared to PVC, making it suitable for high-temperature applications. It is also resistant to abrasion, chemicals, and environmental factors, enhancing the durability and longevity of PV cables. XLPE is known for its excellent moisture resistance and low dielectric losses, making it an ideal choice for outdoor and underground PV installations.

3. Ethylene Propylene Rubber (EPR):

Ethylene propylene rubber, or EPR, is a synthetic rubber material known for its high flexibility, thermal stability, and resistance to weathering and UV exposure. EPR insulation is commonly used in medium-voltage PV cables due to its excellent electrical properties and mechanical strength. It can withstand a wide range of temperatures and environmental conditions, making it suitable for both indoor and outdoor PV applications. find out here now is also environmentally friendly and recyclable, aligning with the sustainability goals of the solar energy industry.

4. Thermoplastic Elastomers (TPE):

Thermoplastic elastomers, or TPE, are a versatile class of insulation materials that combine the properties of thermoplastics and elastomers. TPE insulation offers good flexibility, abrasion resistance, and weatherability, making it suitable for PV cables exposed to harsh environmental conditions. TPE materials are also recyclable and environmentally friendly, contributing to the sustainability of PV systems. TPE insulation is commonly used in flexible PV cables and connectors, providing reliable electrical insulation and mechanical protection.

Properties of PV Cable Insulation Materials:

1. Electrical Insulation:

One of the primary functions of insulation materials in PV cables is to provide electrical insulation to prevent short circuits and electrical faults. Insulation materials such as XLPE and EPR have high dielectric strength, allowing them to withstand high voltages and electrical stresses. Good electrical insulation properties ensure the safe and reliable operation of PV systems, protecting components and personnel from electrical hazards.

2. Thermal Stability:

PV cables are exposed to a wide range of temperatures, especially in outdoor installations where they are subject to sunlight exposure and temperature fluctuations. Insulation materials with high thermal stability, such as XLPE and EPR, can withstand elevated temperatures without degrading or losing their insulating properties. Thermal stability is crucial for the long-term performance and reliability of PV cables, ensuring they can operate effectively in varying environmental conditions.

3. Moisture Resistance:

Moisture is a common environmental factor that can degrade the performance of PV cables over time. Insulation materials with good moisture resistance, such as XLPE and TPE, can prevent water ingress and maintain their electrical properties in wet conditions. Moisture-resistant insulation is essential for outdoor PV installations exposed to rain, snow, or humidity, ensuring the longevity and safety of the entire PV system.

4. UV Resistance:

Solar panels and PV cables are exposed to sunlight, which contains ultraviolet (UV) radiation that can degrade materials and cause premature failure. Insulation materials with UV resistance, such as EPR and TPE, can withstand prolonged exposure to sunlight without cracking, fading, or losing their insulating properties. UV-resistant insulation is critical for outdoor PV applications to ensure the durability and performance of cables over their operational lifespan.

Advantages and Disadvantages of PV Cable Insulation Materials:

1. PVC:

Advantages:

- Cost-effective

- Good electrical insulation properties

- Flexibility

- Resistance to moisture and sunlight exposure

Disadvantages:

- Limited temperature resistance

- Environmental impact

2. XLPE:

Advantages:

- Superior thermal and electrical properties

- Excellent moisture resistance

- Low dielectric losses

- Durability and longevity

Disadvantages:

- Higher cost compared to PVC

- Limited flexibility in some applications

3. EPR:

Advantages:

- High flexibility

- Thermal stability

- Resistance to weathering and UV exposure

- Environmentally friendly

Disadvantages:

- May have higher cost compared to PVC

- Limited availability in certain configurations

4. TPE:

Advantages:

- Versatile properties

- Good flexibility and abrasion resistance

- Weatherability

- Recyclable and environmentally friendly

Disadvantages:

- May have higher cost compared to PVC

- Limited temperature resistance in some applications

Applications of PV Cable Insulation Materials:

1. PVC:

- Residential and commercial rooftop solar installations

- Low-voltage PV systems

- Temporary PV installations

2. XLPE:

- Utility-scale solar farms

- High-voltage PV systems

- Underground PV cables

3. EPR:

- Medium-voltage PV systems

- Solar power plants

- PV cables in harsh environmental conditions

4. TPE:

- Flexible PV cables and connectors

- Portable solar panels

- Outdoor PV installations

Conclusion:

PV cable insulation materials play a critical role in ensuring the safety, durability, and efficiency of solar energy systems. By understanding the types, properties, advantages, disadvantages, and applications of insulation materials such as PVC, XLPE, EPR, and TPE, stakeholders in the solar energy industry can make informed decisions when selecting suitable materials for PV cables. Each insulation material has its unique characteristics and suitability for different PV applications, allowing designers and installers to choose the best option based on specific project requirements and environmental conditions. As the solar energy industry continues to grow, the demand for high-quality and reliable insulation materials for PV cables will only increase, driving innovation and sustainability in the field of renewable energy.